1- What is traceability?

This is a request from more and more buyers around the world for goods and products to be acquired from suppliers for which key parameters such as quality controls, compliance with mandatory standards, presence of critical components or hazardous substances must be traceable up to the subcontractor or the sub-supplier of raw materials. Tag-N-Trace supplies this service online 24/7/365 at a highly competitive price, using the latest advances in RFID or barcode technologies.

2- Will traceability become mandatory?

To limit the risk of non-quality of export products in international trade, more and more governments around the world are studying the possibility of establishing a mandatory traceability system that ensures the identification of key quality parameters covering the manufacturing chain through to the retail market. Prepare your company now for this new challenge.

3- Does traceability encompass product conformity?

Most products must comply with international or regional quality and safety standards. One key feature of Tag-N-Trace is a product ID card embedded in the product that stores all information related to the product’s compliance with set standards: the reference for the standard, type of certification, testing laboratory involved in the certification process, validity of the Certificate of conformity.

4- Is traceability protecting my company against counterfeits?

Thanks to a product ID card embedded in the product, its origin and genuineness can easily be verified. Any registered user, retailer or consumer can do this online 24/7/365 by simply entering the TIN (Tag Identification Number) on the Tag-N-Trace web site. Suppliers can therefore easily protect their products against counterfeits and offer customers a guarantee of their origin and genuineness.

5- Is traceability part of my clients’ expectations?

International buyers as well as end-users/consumers are becoming increasingly demanding in terms of quality, safety, conformity and genuineness of products bought through international trade. The only way to satisfy this need is by means of a traceability system that is easy to use, based on tags embedded in the product and giving the access to a central online database where the product’s detailed ID card can be consulted 24/7/365.

6- How much does it cost?

The cost of the service is calculated in proportion of the number of products in a given batch.

- For RFID technology: 0,15 USD per product (NOT including the RFID tag)

- For Bar code technology: 0,05 USD per product

For a batch of 10,000 items it would cost you USD 1,500 if you choose the RFID solution and USD 500 if you choose the bar code technology. For the RFID solution you must add the cost of the tag itself, which is in the range of USD 0.35 per item. In addition, you will need to invest in an RFID encoder at a cost of around USD 2,000 to USD 5,000 depending on the quantity

7- What is RFID?

RFID technology can deliver benefits in many areas, from tracking work in process to speeding up throughput in a warehouse. Radio-frequency identification (RFID) is an automatic identification method, relying on storing and remotely retrieving data using devices called RFID tags or transponders. An RFID tag is an object that can be stuck on or incorporated into a product, animal, or person for the purpose of identification using radiowaves. Some tags can be read from several meters away and beyond the line of sight of the reader. Most RFID tags contain at least two parts. One is an integrated circuit for storing and processing information, modulating and demodulating a (RF) signal and perhaps other specialized functions. The second is an antenna for receiving and transmitting the signal. A technology called chipless RFID allows for discrete identification of tags without an integrated circuit, thereby allowing tags to be printed directly onto assets at lower cost than traditional tags. Today, a significant thrust in RFID use is in enterprise supply chain management, improving the efficiency of inventory tracking and management.

8- Is RFID better than bar code?

RFID is not necessarily “better” than bar codes. The two are different technologies and have different applications, which sometimes overlap. The big difference between the two is bar codes are line-of-sight technology. That is, a scanner has to “see” the bar code to read it, which means people usually have to orient the bar code toward a scanner for it to be read. Radio frequency identification, by contrast, doesn’t require line of sight. RFID tags can be read as long as they are within range of a reader. Bar codes have other shortcomings as well. If a label is ripped or soiled or has fallen off, there is no way to scan the item, and standard bar codes identify only the manufacturer and product, not the unique item. The bar code on one milk carton is the same as every other, making it impossible to identify which one might pass its expiration date first.

9- Can I use my own RFIDs?

We strongly recommend that you use our RFIDs, which are OEM technology bought from Texas Instruments, the world leader in the field. This will guarantee you top-quality RFIDs and create the confidence that is indispensable between your customers and your company. Last but not least, our offer price for top-notch RFIDs is highly competitive compared with low-end RFIDs from unreliable sources.

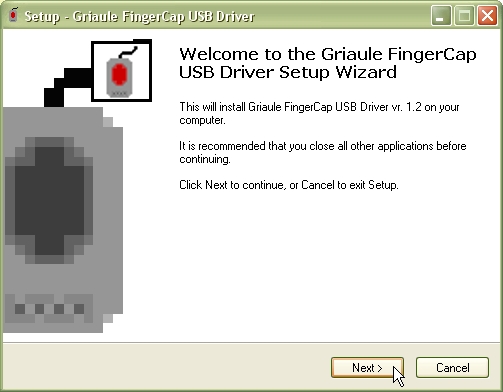

STEP1: Download the Fingerprint Reader Drivers

STEP2: Install Drivers and follow the instructions

STEP3: Plug the Fingerprint Reader